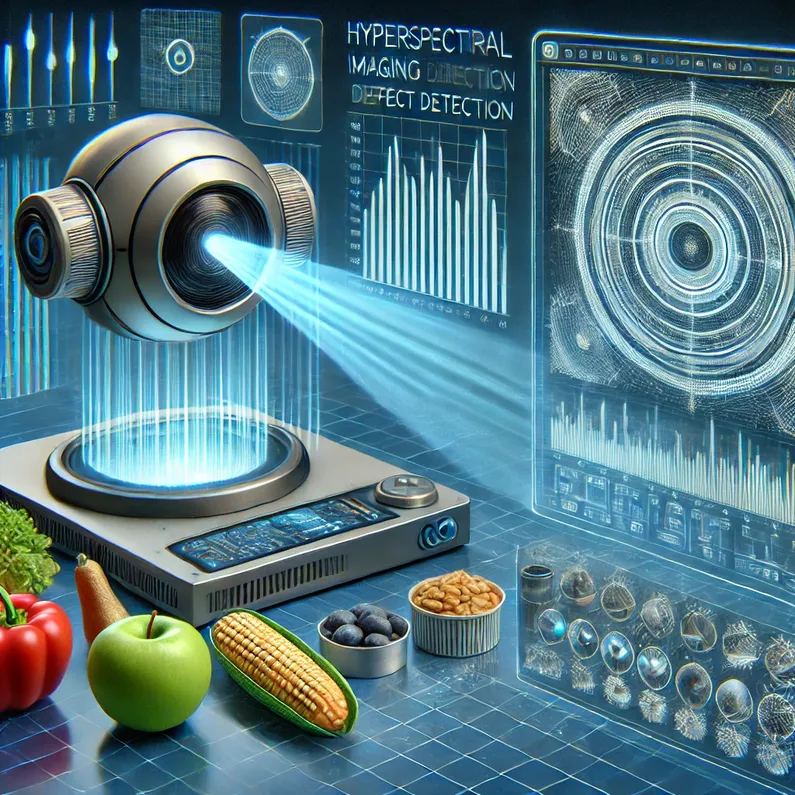

Detection and Identification of Defects Using Artificial Intelligence Analysis of Multi-Dimensional Information Data

Introduction

AI advancements have revolutionized defect detection in various samples. United States Patent Application No. 20250005942, titled “Detection and Identification of Defects Using Artificial Intelligence Analysis of Multi-Dimensional Information Data,” details novel techniques for analyzing defects in materials, from food to abiotic objects.

Primary Objective

The invention aims to develop an AI-based system for defect detection through multi-dimensional image data analysis, focusing on wavelength patterns critical for identifying pathogens in food and other materials.

System and Methods

- Imager The imager uses a hyperspectral array of filter lenses to capture multi-dimensional data, surpassing conventional RGB imaging by covering a broader range of wavelengths.

Integration of imaging devices, including mobile phone cameras and handheld microscopes, enhances the system’s versatility for laboratory and non-laboratory settings. - Artificial Intelligence Module The AI module identifies defects in multi-dimensional image data. Using a hypercomplex neural network and Deep Hypercomplex based Reversible Data Reduction (DHRDR) ensures high accuracy.

Data augmentation through generative adversarial networks (GANs) synthesizes additional multi-dimensional data, improving robustness. - Analysis Module This module detects and classifies defects. A data reduction module streamlines multi-dimensional data analysis, while a feature recalibration module enhances image content using spectral and spatial attention paths, boosting detection accuracy.

Background

Various systems inspect objects based on specific criteria. Image processing systems analyze inputs like photographs and videos, often treating the image as a 2D signal. Techniques include image enhancement, restoration, compression, segmentation, recognition, and smoothing.

RGB-based systems identify regions with defined characteristics but may be inadequate for predicting vegetable softness, quality, and microbial spoilage. Traditional food safety systems may also be inefficient. Foodborne pathogens cause numerous diseases, significantly impacting health. Despite safety measures, millions of foodborne illness cases occur annually, incurring significant costs.

Foodborne illnesses arise when pathogens are ingested with food and establish themselves in the host or produce toxins. They are classified into foodborne infections and intoxications. Common pathogens include Bacillus cereus, Campylobacter jejuni, Clostridium botulinum, Clostridium perfringens, Cronobacter sakazakii, Escherichia coli, Listeria monocytogenes, Salmonella spp., Shigella spp., Staphylococcus aureus, Vibrio spp., and Yersinia enterocolitica.

Contaminated food can originate from synthetic, plant, or animal sources. Routine pathogen testing methods, like culture-based methods using selective media, remain the gold standard, but results can take days. Long testing times, small sample sizes, and human handling delay commerce and increase cross-contamination risks.

Optical detection methods rely on generating and detecting fluorescence, Raman, or other excited signals, requiring powerful, costly sources. These methods involve extensive sample preparation. Instruments based on these mechanisms typically cannot differentiate between serotypes and species. Non-optical methods, like nucleic acid-based polymerase chain reaction (PCR), detect target pathogens but are costly. LAMP (loop-mediated isothermal amplification) is an alternative in some assays.

Summary

This invention provides methods, apparatus, and program products for detecting defects in a sample using an AI module to analyze images. The AI module identifies defects within multi-dimensional image data, such as hyperspectral data. In some embodiments, samples include food, and defects include pathogens.

The system includes an AI module that measures color temperature during image acquisition, classifying defects regardless of color temperature. It features a multi-dimensional neural network with dedicated dimensions for different data components. For foodborne pathogen detection, the system detects pathogens in real-time in both laboratory and non-laboratory settings.

System Configuration:

- Imager: Acquires images using mobile phone cameras and handheld microscopes.

- Artificial Intelligence Module: Identifies defects within multi-dimensional data, including hyperspectral and color temperature data.

- Analysis Module: Detects defects based on wavelength patterns, including data reduction and defect classification hierarchies.

- Feature Recalibration Module: Enhances image content using spectral and spatial attention paths.

Unique Aspects

The system offers advantages like hyperspectral filters and advanced AI algorithms for improved accuracy and efficiency. It processes multi-dimensional data as one-dimensional signals and uses different neural networks for various defect classification levels.

Hyperspectral imaging captures a broad spectrum of light, providing detailed information to differentiate materials and defects. Advanced AI algorithms learn from vast data, improving accuracy and reliability. The feature recalibration module focuses on relevant spectral and spatial features, ensuring accurate identification of subtle defects.

Usage Examples and Impact

This technology detects pathogens in food products and analyzes abiotic objects for defects, significantly impacting industries by ensuring higher safety and quality standards.

In the food industry, quick pathogen detection is crucial for maintaining food safety. The system’s real-time detection allows immediate removal of contaminated products, reducing illness risks. Its non-laboratory setting capabilities make it ideal for food processing plants and retail locations.

For abiotic objects, the system inspects industrial components and products for defects, ensuring high-quality items reach consumers, reducing failures. Its versatility makes it valuable for quality control and defect detection across industries.

Future Research and Development

Future research could enhance AI algorithms, integrate additional sensors, and expand applications. Improvements may include faster real-time analysis and broader applicability.

Research could explore integrating thermal imaging for complementary data, improving detection accuracy. Advanced AI developments, like sophisticated neural networks, could enhance learning from smaller datasets and generalization.

Collaborating with industry partners and regulatory bodies could refine performance, ensuring safety and quality standards. Adapting to new challenges will make this technology indispensable.

Conclusion

This system advances defect detection using AI and multi-dimensional data analysis, offering a robust solution for improving safety and quality control. Future developments will expand capabilities, driving innovation.

Disclaimer

The author of this article expresses sincere respect and gratitude to the inventors of the described technical solution: Karen A. Panetta (Rockport, MA, US), Sos S. Agaian (New York, NY, US), Shishir Paramathma Rao (Burlington, MA, US), Srijith Rajeev (Burlington, MA, US), Mohandas Shreyas Kamath Kalasa (Burlington, MA, US), Rahul Rajendran (Belleville, MI, US), and Jessica White (New York, NY, US), as well as to its Assignees, Trustees of Tufts College (Medford, MA, US) and Research Foundation of the City University of New York (New York, NY, US).

This article reflects the author’s opinion and is provided for informational purposes only. It does not constitute legal or professional advice. For more precise information, consultation with qualified professionals is recommended.

Source of Patent Information:

https://www.freepatentsonline.com/y2025/0005942.html

Image Disclaimer

This illustration was created using the DALL·E (OpenAI) tool and is included solely for illustrative purposes under OpenAI’s usage terms. Any further use, alteration, or distribution of this image by the purchaser (or third parties) is at their own discretion and responsibility. Please consult OpenAI’s terms for more information.